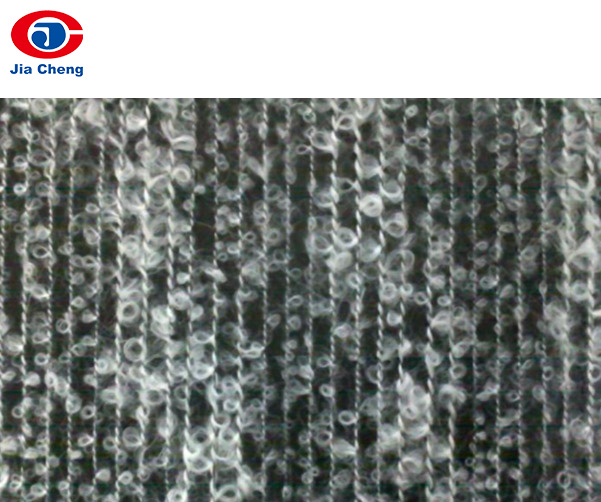

The roving with or without twist is fed into the machine.After three rollar apron drawing,the fiber bundles meet the core wire and the solid wire at the front rollar exit.By twisting and untwisting hollow spindles and rings.Various fiber-type Fancy Yarns are formed.The docorative yarn can be directly drawed with the core yarn and the solid yarn at the exit of the Front Rollar.

Hot selling fancy polyester fiber yarn twisting machine

Application

The roving with or without twist is fed into the machine.After three rollar apron drawing,the fiber bundles meet the core wire and the solid wire at the front rollar exit.By twisting and untwisting hollow spindles and rings.Various fiber-type Fancy Yarns are formed.The docorative yarn can be directly drawed with the core yarn and the solid yarn at the exit of the Front Rollar.

Main Features

For the convenience of user to change patterns,the machine adopts six frequency comverters.Control Core Roller,middle and rear roller,front roller,output roller,hollow ingot continously variable speed respectively.PLC Programmable Controller and touch screen programs are used to change process parameters,display parameters and save 100 groups of process parameters.For customers to facilitate the development of new products and samples imitation.In the trial production process,the above mentioned six parts can be fine-tuned speed.

Technical parameter

Machine type | JC160HN |

Spindle Gauge | 150mm |

Quantity of spindles | 16spindles*section number(Max13sections) |

Front- rear roller diameter | 45mm |

Middle roller diameter | 26mm |

Core roller diameter | 40mm |

Output roller diameter | 45mm |

Ring diameter | 90mm |

Hollow spindle rotate speed | 6000-9000rpm |

Lfft stroke | 220-300mm |

Draft ratio | 1-30times |

Rotal power | 45.5kw |

Copyright © 2021 Jiangsu Jiacheng Technology Co.,Ltd All Rights Reserved.